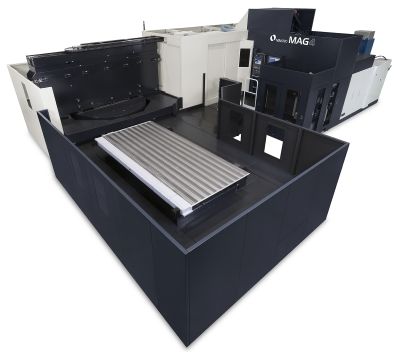

Makino's MAG4 HMC Perfect for Larger Wing and Fuselage Assembly Components

The MAG4 expands Makino's MAG Series of 5-Axis horizontal machining centers purpose built for monolithic aluminum aerostructure components.

At the heart of the MAG4 is the powerful 33,000 RPM 130kW spindle. This is the same spindle utilized across the MAG family and provides peak roughing metal removal capabilities of up to 10 liters per minute. Y-axis stroke is increasing to 2,200mm (X4000 Y2,200 Z800) and pallet size is increasing to 3,500 x 2,000mm.

The compact A/C rotary axis has a very short 215mm pivot distance allowing full 5-axis access to parts as large as 3,300 x 1,500mm. The MAG4 includes a large capacity tool magazine and pallet changer with horizontal work setting stations supporting high spindle utilization.

VIDEO: Taking 5-Axis Aerostructure Machining to New Levels: Introducing the Makino Mag4 5-Axis HMC

The MAG4 5-Axis Horizontal Machining Center is ideally suited for high-productivity aerospace machining of complex aluminum monolithic parts.

With larger X and Y travels and a pallet size compared to MAG3 machines, the MAG4 provides 5-sided accessibility to larger structural components like wing ribs. The MAG4 integrates the 33k RPM / 130 kW spindle with rapid acceleration and through-spindle coolant capability to maximize metal removal rates. The MAG4 is compatible with the proven Makino MMC2 automatic pallet transfer and storage system for extended periods of unattended production.

The MAG4 integrates spindle speed and power with a machine platform that provides rapid precision-contouring capability while maximizing the percentage of in-cut spindle time. The compact spindle and short pivot point provided ideal five-face workpiece accessibility to minimize setups and process variation.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::