Renishaw's Tempus Technology Reduces AM Build Times Up to 50% -- Lowers Cost per Part

Renishaw's new TEMPUS™ technology enables users of RenAM 500 series metal additive manufacturing (AM) systems to reduce build times by up to 50 percent. The technology uses advanced scanning algorithms that sequence the layer data to maximize productivity while maintaining part quality.

The optimization suits some part geometries more than others, but all geometries can see some productivity benefits. Parts with thin, vertical features, for example, are likely to experience proportionally higher productivity savings.

TEMPUS technology is standard with the new RenAM 500 Ultra system, as well as advanced process monitoring software. The combination of significantly reduced build times and detailed build insights means that the RenAM 500 Ultra delivers cost-effective, reliable additive manufacturing for metal component production, according to the company. Existing RenAM 500 series customers can access TEMPUS technology as a paid-for upgrade, to make the most of their machine investment.

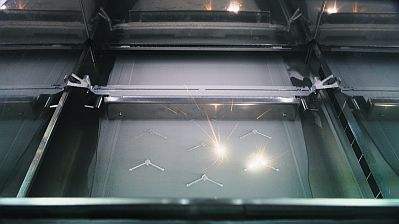

While traditional powder bed systems require the powder recoater to fully distribute powder before the layer can be consolidated, with TEMPUS technology, the lasers can fire at the same time as the recoater is moving. The patented technology employs seamless communication between advanced software and hardware components to synchronize the system lasers with the powder recoater, removing up to nine seconds of build time from every layer. With builds frequently containing thousands of layers, this can reduce total build times by tens of hours. Yet crucially, there is no reduction in part quality.

The technology uses advanced scanning algorithms that sequence the layer data in a way that maximizes productivity while maintaining part quality. The optimization suits some part geometries more than others, but all geometries can see some productivity benefits. Those parts with thin, vertical features, for example, are likely to experience proportionally higher productivity savings.

VIDEO: Why the RenAM 500Q?

"Reducing cost per part is critical to the wider adoption of AM technology," explained Louise Callanan, Director of Additive Manufacturing at Renishaw. "The dominant contributing factor to part cost for most components today is the time spent building the part on the machine itself. Reducing the amount of machine time per part therefore results in more cost-effective production."

This new technology will be on display at the Renishaw Additive Manufacturing exhibit at the Additive Manufacturers User Group (AMUG) in Chicago March 30-April 3, and at RAPID in Detroit April 8-10.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::