SPEE3D Develops Ultra-Corrosion-Resistant Alloy -- A Game-Changer for Maritime Additive Manufacturing

Australian manufacturer SPEE3D has developed two grades of an ultra-corrosion-resistant Nickel Aluminum Bronze alloy that is compatible with its Cold Spray Additive Manufacturing (CSAM) technology. The powder material is a game-changer for maritime OEMs and the U.S. Navy as it will help with supply chain delays and keep critical maritime systems operational.

Not all metals possess the properties and corrosion resistance needed to withstand the tough conditions faced by ships and maritime vessels. Nickel Aluminum Bronze (NAB), however, is one of a small number of metal alloys that can.

SPEE3D has developed a commercially available Nickel Aluminium Bronze Expeditionary material, designed to be field-deployed and enable production of parts in hours, not days.

Today, NAB is broadly used in the maritime industry in the production of ship valves, propellers and other components, as it offers high strength, anti-microbial, antifouling and corrosion resistant properties. Typically, NAB components are manufactured using casting processes, however this manufacturing approach is burdened by certain limitations, like the need for costly tooling, long turnaround times and complex logistics.

Being able to additively manufacture NAB parts has therefore been of keen interest to maritime OEMs and ship maintenance crews. However, working with the metallic alloy has presented challenges due to the material's complexity and the standards needed to ensure the quality and performance of NAB parts for maritime applications.

Easily deployed, XSPEE3D can be powered up and ready to fabricate parts up to 88lbs immediately in remote locations and harsh conditions.

Up until now, that is.

Australian manufacturer SPEE3D has developed and released a Nickel Aluminum Bronze alloy compatible with its Cold Spray Additive Manufacturing (CSAM) technology.

The powder material is a game-changer for maritime OEMs, who can now 3D print ship parts at the point of need (including at forward bases, at ports or directly onboard), dramatically reducing production times and costs.

The Gold Standard for Maritime

The newly released 3D printing metal was developed through a collaboration between SPEE3D and the US Naval Sea Systems Command (NAVSEA) to address the hurdles of increasingly unstable supply chains and the costs associated with casting NAB parts.

VIDEO: How Nickel Aluminium Bronze benefits naval and maritime

After extensive development and evaluation, SPEE3D successfully developed two NAB powder feedstocks: an exclusive material for NAVSEA that meets specific requirements for its maritime applications, and a commercial grade (Expeditionary) that has 97% of the former's properties.

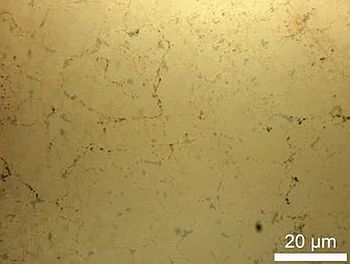

Both grades of the NAB material are engineered for use with SPEE3D's CSAM technology, an automated process that builds parts additively by spraying metal particles onto a substrate using compressed air that can reach supersonic speeds. The kinetic energy generated by the speed of the cold spray results in metal particles that bind together for a dense metal component with low porosity. The CSAM process is also notable for its lack of extreme temperature variations, which translates to a lower risk of residual stresses in parts, including minimized risk of cracks, warping and distortions.

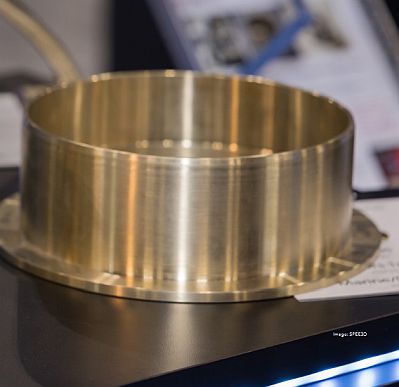

SPEE3D manufactured a 1.7 kg camlock fitting that was 3D printed in half an hour.

The NAB powder certified for NAVSEA use, called C958 NAB, requires a combination of conventional and Hot Isostatic Pressing (HIP) heat treatments to produce defect-free parts with "the correct composition and hardness condition, including the Nb required by the B369 specification for weldability."

This slightly higher caliber material is intended for the production of safety-critical parts for surface and sub-surface maritime vessels and effectively enables end users to produce "fully compliant, like-for-like" replacement parts. The commercial grade NAB powder, for its part, does not require HIP heat treatments, offering a more accessible and cost-effective pathway to 3D printing NAB maritime parts with high strength (58 ksi, 390MPa UTS) and corrosion resistance.

This material grade is ideal for manufacturing temporary replacement parts to address supply chain delays or shortages and keep critical maritime systems operational while the permanent replacement part is delivered.

Expeditionary NAB does require a simplified heat treatment process, such as homogenization, but can be easily used onboard ships that operate SPEE3D's Expeditionary Manufacturing Unit, which was released in May 2024 and is particularly well suited to point of need manufacturing as it integrates the XSPEE3D metal 3D printer with SPEE3Dcell post-processing and testing unit in two 20-foot shipping containers.

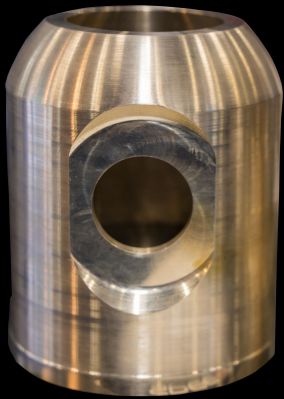

NAB Propeller Housing after machining a cut out.

As the company puts it: "SPEE3D's EMU system can manufacture an Expeditionary grade NAB most places on the planet with an adequate power supply and a handful of flat ground. We see this as game-changing technology in the sustainment of civilian and military marine equipment."

NAB Applications in Maritime

The nature of the CSAM process, which applies metal layers to a substrate, makes it ideal for ship maintenance and repair operations.

Now, with the ability to print with NAB, maritime end users can repair NAB parts or print replacement parts onboard, while also benefiting from the material's lubricity, resistance to cavitation damage and, of course, its extreme corrosion resistance.

The potential maritime applications for the new Nickel Aluminum Bronze alloy are numerous. To demonstrate this versatility, SPEE3D has already printed a number of sea-worthy parts, including a propeller strut (which weighed 11.3 kg and was printed in just three hours), a 6.9 kg bushing which only took two hours to manufacture and a 1.7 kg camlock fitting which was printed in half an hour.

The Nickel Aluminum Bronze alloy features excellent corrosion resistance, high strength, anti-galling, and anti-biofouling.

Other applications include ship rudders, propeller shafts, valve bodies, pipe fittings and engine infrastructure. The maximum build volume of the CSAM technology is up to one meter in diameter and 0.7 meters in height -- or up to 40 kg. SPEE3D emphasizes that cast-equivalent metal parts of this scale can be printed in mere hours, rather than weeks.

Of course, the material also has applications outside of the maritime segment. As Byron Kennedy, CEO of SPEE3D explains: "NAB Expeditionary is a great solution for other industries as well: defense, oil and gas and mining, for example. Parts can be field produced and delivered in under 24 hours, making it an extremely fast and reliable way to keep operations running."

SPEE3D's Maritime Focus

SPEE3D has been active in the maritime AM sphere for some time now, with a particular focus on working in collaboration with defense organizations, such as the Australian and British Armies, NAVSEA and the US Naval Postgraduate School.

The Australian company also has a range of other material grades suitable for maritime applications, including the low-corrosion aluminum alloy Al 6061; aluminum bronze, which has exceptional corrosion resistance to sea water; corrosion resistant and ductile stainless steel; and copper.

SPEE3D's new NAB materials will solidify the company's ability to serve the maritime market and will undoubtedly push the adoption of 3D printing by maritime end users and beyond.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::