Kawasaki Launches Industrial-Grade Cobots

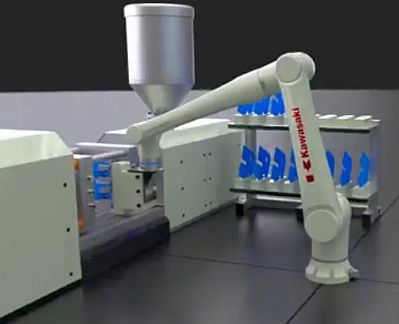

Kawasaki Robotics' new CL Series of intelligent collaborative robots (cobots) is designed for applications such as welding, machine tending and material removal.

"Kawasaki Robotics is committed to delivering the advanced automation technology manufacturers need to maintain production schedules without having to compromise quality or safety," said Seiji Amazawa, President, Kawasaki Robotics.

Developed in partnership with NEURA Robotics, the CL Series cobots challenge the current understanding of collaborative robots, offering full-on industrial scale performance and speed paired with maximum protection without compromising the safety and flexibility advantages of human/robot collaboration.

Compact and robust, using the same durable casing as Kawasaki Robotics' industrial robot arms, the CL Series cobots can operate without protective covers in crowded and harsh environments that may not be suitable for other cobots. Operating in Zero Gravity (Zero G), the CL Series cobots require only light guidance and precise adjustments by hand to create highly efficient solutions for applications such as machine tending and welding.

VIDEO: Kawasaki Robotics CL Series Collaborative Robots

"With our CL Series cobots, we're entering a new era of collaborative automation," Amazawa said. "By providing advanced capabilities along with industrial scale performance and speed as standard features, we boost productivity, improve product quality and worker safety, and reduce rework requirements. Our entirely new way and agile approach to collaborative robots enables manufacturers to more easily address labor shortages while yielding excellent return on investment."

The CL Series cobots support a variety of payloads and reach from 3 kg/590 mm to 10 kg/1000 mm, with higher payloads such as 15kg expected to hit the market within the next year.

Built with high-quality components such as integrated 24-bit encoders, the CL Series operates with industry-leading speed of 200°/s and a repeatability of +/- 0.02 mm. The intuitive user interface makes automating production lines easier than ever before.

Free mounting orientations, extremely small footprint, and IP66 classification provide unparalleled flexibility. The proprietary safety architecture includes such features as limits and collision detection, enabling CL Series cobots to operate reliably alongside human workers.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::