Cobots and AI: Stars of the Show at IMTS

While the first robot hand was introduced at IMTS in 1988, the excitement surrounding collaborative robots has taken off this past decade. Universal Robots has spearheaded this latest trend. The company made its first appearance at IMTS in 2012. By 2016, collaborative robots (cobots) had emerged as one of the hottest topics at the show.

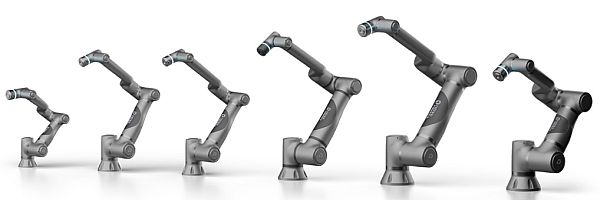

This year, at IMTS 2024, visitors walking the aisles could hardly pass 4 or 5 booths without seeing another cobot arm integrated into that company's operation. While they all seem to maintain a similar look to UR's original version introduced 12 years ago, many more robotic companies have entered the cobot field.

Rethink Robotics returned to the market and unveiled its Rethink Reacher (RE) line of cobots. After a hiatus, Rethink Robotics is celebrating its comeback with a renewed company vision, aiming to serve the North American market with better, faster, and stronger products and solutions.

Kawasaki Robotics introduced new additions to its extensive robotics portfolio, including the new CL Series of intelligent collaborative robots. The CL Series cobots, available for order in multiple payloads, and the new industrial robotic solutions featured for applications such as welding, machine tending and material removal give manufacturers limitless flexibility and advanced capabilities when choosing automation to meet their diverse needs.

"With our CL Series cobots, we're entering a new era of collaborative automation," said Seiji Amazawa, President, Kawasaki Robotics. "By providing advanced capabilities along with industrial scale performance and speed as standard features, we boost productivity, improve product quality and worker safety, and reduce rework requirements."

Meanwhile, at the Universal Robots' booth, the cobot pioneer demonstrated its new commitment to AI by unveiling a new AI-powered machine tending solution, enabling faster batch changeovers by eliminating the need for fixtures. Additionally, the company showcased advanced cobot applications for welding, finishing, part feeding, and laser marking.

When Universal Robots recently surveyed 1,200 manufacturers across North America and Europe about their use of technology and future investment plans, over 50% of the respondents indicated they are now using AI and machine learning in their production processes, "AI isn't just hype," says Ujjwal Kumar, Group President of Teradyne Robotics, parent company of Universal Robots. "We're seeing significant interest in physical AI. By adding high-performance computer hardware to our control systems and investing in targeted software upgrades, we're establishing UR as the preferred robotics platform for developing and deploying AI applications."

UR's machine-tending application features new AI-based perception capabilities running on NVIDIA Jetson and Isaac acceleration libraries integrated into UR's new PolyScope X platform. This combination enables dynamic path planning, ensuring the robot takes the most effective, collision-free paths in and out of the machine without requiring extensive user configuration. UR plans to make this cutting-edge technology available for a wide range of applications, including machine tending and other material handling tasks.

The UR+ ecosystem recently hit a milestone, announcing 500 UR+ products. At UR's IMTS booth, the following UR+ products were displayed:

- Brinkman Automation's "The Finisher" -- the world's first automated modular deburring, polishing, and cleaning cell powered by a UR5e cobot.

- Hirebotics' Cobot Welder integrated with Miller's Auto DeltaWeld, an advanced welder for cobot welding applications.

- Hurco's VM15Di 3-axis CNC machine featuring tending by a UR20 cobot, UR's longest reach cobot.

- Laser Marking Technologies' Cobalt® Dominator, tended by a UR3e cobot with OnRobot's VGC10 gripper.

- Lights Out Manufacturing's Aries 10 part feeder application featuring a UR30 cobot that allows for lightning-fast part changeovers.

- Vectis Automation's Park'N'Arc range extender for welding applications featuring the UR20 cobot.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::