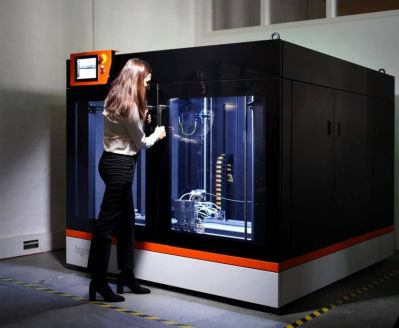

New Large-Scale BigRep Printer Designed for Automated, Non-Stop 3D Printing of Industrial-Grade Parts

[All photos courtesy BigRep]

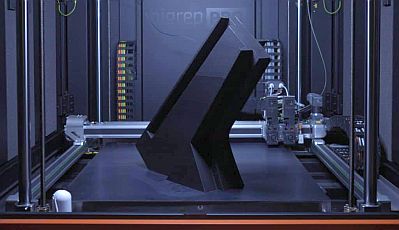

BigRep has released a brand-new industrial Fused Filament Fabrication (FFF) 3D printer, the VIIO 250 -- their most automated large-scale machine made to print engineering-grade and fiber-reinforced materials. The 3D printer is built to produce large, high-resolution parts as effortlessly as possible so users can press print, and the machine takes it from there with little to no manual intervention.

The breakthrough features for uninterrupted printing are the seamless automatic filament handling aptly named Infinity Box and the backup extruder functionality called Relay Mode both of which enable around-the-clock production. It also has a new controls platform delivering industrial CNC quality and the convenience of over-the-air software updates.

The other key features of the 3D printer are the temperature-controlled build chamber of 250 liters (1000mm X 500mm X 500mm) that reaches 50°C, an open material system compatible with BigRep and third-party filaments, and dual Smart Manufacturing Extruders (SMX) that heat up to 350°C. The machine has a new upgrade that is a hit among the first users -- an intuitive human machine interface (HMI), that comes in multiple languages and has animated guides to steer users through standard operations.

The machine is positioned for sectors in industrial manufacturing, especially the automotive industry, where unattended operation can be a game-changer. Designed for high efficiency, the VIIO 250 enables affordable production of functional parts with reduced energy consumption.

Dr.-Ing. Sven Thate, Managing Director of BigRep GmbH commented, "The VIIO 250 is a significant leap forward in automating and simplifying 3D printing technology aiming to advance industrial users' productivity. By integrating advanced automation features and user-friendly interfaces, we aim to set a new standard for efficiency, ease of use, reliability, and repeatability in large-scale industrial-grade 3D printing striving to continuously improve customers' Overall Equipment Efficiency (OEE) and Total Cost of Ownership (TCO). With this we are setting the foundation for widespread adoption of large-format Additive Manufacturing (AM) in series production of large, accurate, strong parts in industrial manufacturing."

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::