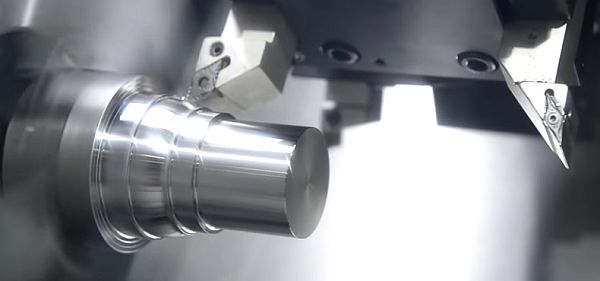

New Gen HTC's Sub-Spindle Enables Off-Center Milling

Credit: Romi

Romi's New Generation GL 300S horizontal turning center is equipped with a sub-spindle and a Y-axis for off-center milling.

With a maximum cutting diameter of 11.8" (300 mm) and Z-travel of 23.6" (600 mm), it is designed for turning, milling, and drilling operations in high-production environments. The GL 300S features high power torque and feed force and is built with a robust "Romi-made" monoblock base for ultimate rigidity and precision. The machine weighs in at 11,464 lbs. (5200 kg).

VIDEO: ROMI GL 300S

The New Generation GL 300S comes equipped with thermal compensation with sensors to maintain stable, dimensional results even during long working periods. The use of sensors provides accurate, real-time compensation as opposed to compensation based only on pre-defined algorithms. The result is more accurate as the machine temperature increases over extended periods.

Credit: Romi

It is equipped with durable roller ways on all axes, ensuring high rigidity and longevity. The 12-station BMT55 turret with driven tools and a Y-axis further enhances its versatility and durability. The built-in spindle and sub-spindle motors, with chiller incorporated and direct drive servo motors, produce high response speed and accuracy and require less maintenance. Chilling the motor increases life expectancy and produces less thermal expansion, making it a cost-effective choice in the long run.

The CNC control is a Fanuc 32iB with a 19" LCD touchscreen. It is designed to produce faster, more accurate performance for turning applications with separate areas on the main screen for planning, machining, improvements, and utilities.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::