Top 25 Automation Manufacturer Implements New ERP System and Improves Productivity by 10%

So, how'd they do it? Read the ways Canadian-based CenterLine -- a specialist in advanced automation processes and joining technologies -- significantly improved its operation around the world.

In automotive factories across the world, welding machines and materials manufactured by CenterLine are used to build the cars we drive and vehicles that deliver essential goods. The Canadian-based, privately held corporation specializes in advanced automation processes and joining technologies for resistance welding, metal forming, and cold spray applications. The vertically integrated enterprise has product offerings ranging from welding consumables to fully automated production systems.

Headquartered in Windsor, Ontario, CenterLine is a privately held corporation that builds custom automated welding and assembly lines.

Primary customers include OEMs and Tier 1 suppliers in the automotive, mass transit, aerospace, and defense industries. These include Magna International, Martinrea International, and Stellantis, which owns brands such as Alfa Romeo, Chrysler, Citroën, Dodge, Fiat and Jeep. Aside from its main operations in Windsor, Ontario, CenterLine has manufacturing and service support facilities in the US, Mexico, Brazil, Germany, Romania, India, and China.

With 65 years of business experience, CenterLine continues to deliver state-of-the-art technologies and processes that help customers maintain a competitive advantage.

Since its founding in 1957, CenterLine has grown from a quarter of its current size to become one of the top 25 automation manufacturers in North America. Demand for its high-quality products and services continues unabated, with the business expanding every year. Meeting that demand was being threatened by an outdated MRP application that impacted manufacturing and procurement efficiencies. The system had been in place for 17 years and could no longer support the business, especially its growth trajectory.

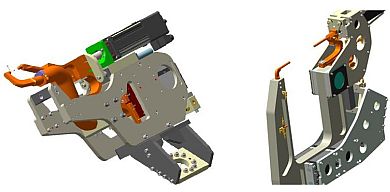

CenterLine's Automation Components Division supplies various resistance welding gun packages, welding actuators, metalworking presses and cylinders, and custom tooling.

"We were struggling with our existing MRP system and making it work effectively for the business," said Darryl Beneteau, CenterLine General Manager. "We had to do lots of manipulation to get the outcomes we wanted. Processes were outdated and could not meet our challenges of getting things done faster and more efficiently."

5,000 Manufacturing Jobs a Week

Driven by customer demand to manufacture more products faster and for less cost, the volumes CenterLine had to manage were too large for the incumbent system. Centerline manages around 5,000 manufacturing jobs every week across its four-building manufacturing site in Ontario.

"Following an extensive evaluation process, CenterLine decided on an Epicor manufacturing ERP solution," shared Beneteau. "The diversity of our manufacturing operation demanded the flexibility that Epicor helps to deliver. Additionally, the Epicor API makes it easy to add features and integrations. We have several self-developed systems -- essential for our complex needs -- and integrating these was much more straightforward and easier than before."

Epicor Kinetic is a global cloud ERP solution designed for and with manufacturers.

CenterLine uses Epicor Kinetic, Epicor Enterprise Content Management (ECM), and Epicor Quick Ship.

Epicor Kinetic is the foundation of the company's operations, supporting functions such as manufacturing, finance, supply chain, HR, and finance. Epicor ECM is an AI-based document management application. Epicor Quick Ship is used to automate many administrative actions associated with shipping products to customers. For example, staff used to go to a UPS and FedEx website and manually type in the shipping details and print a label. Epicor Quick Ship does this automatically, which, with hundreds of shipments a day, saves CenterLine a huge amount of time.

Simple-to-use APIs enable CenterLine to integrate several key applications with Epicor. These include product lifecycle management, materials management, and payroll applications where data is automatically exchanged with Epicor, eliminating the need for time-consuming and manual data input.

VIDEO: Epicor Kinetic Overview

CenterLine spent approximately a year deploying the Epicor solution, but that involved the full Epicor Kinetic platform across four separate manufacturing buildings, a CRM application, a sister company, and 286 individual system processes.

Incredibly Smooth Implementation

"The Epicor implementation was incredibly smooth. We had three Epicor consultants supporting us, and they were fantastic," revealed Beneteau. "They helped with all the technical issues, especially as complexity grew. The cut-over was on time and took just four days, which was remarkable considering the volume of data. We went live on Monday morning and, remarkably, only missed half a day of shipping. There were no major issues, and within a month, the Epicor consultants were hardly needed."

Part of the process to find a new ERP system included establishing a trusted and reliable partnership.

"Epicor has proven to be a good partner, willing to work with us on the challenges we face," explained Beneteau. "That is invaluable to CenterLine because relationships work both ways, and we are seen as a valued voice. Epicor continues to put in the effort to support us even though we are now Live."

CenterLine has used Epicor as a change-management tool to communicate, both shortening and improving manufacturing and procurement processes.

With Epicor, CenterLine has a modern and stable MRP system that helps to deliver significant efficiency gains in the company's core manufacturing operations. "CenterLine is a manufacturer, and the efficiency improvements we have gained with Epicor are fundamental to the business," said Beneteau. "The benefit is not just cost savings; it is also increasing volume and getting more done quickly. CenterLine has a growth trajectory, and increasing capacity is critical. The growth inhibitor was processed, and the ability to execute, and Epicor has alleviated that bottleneck."

Improving Productivity

The company benchmarked manufacturing processes before and after Epicor and found steps-to-complete across 82% of jobs has been reduced by 10%. "Across four to five thousand jobs a week, a 10% improvement in productivity is a significant saving," observed Beneteau.

CenterLine has a growth trajectory and increasing capacity is critical. The growth inhibitor was processes and the ability to execute, and Epicor has alleviated that bottleneck.

"We used Epicor as a change-management tool to communicate, both shortening and improving manufacturing and procurement processes."

CenterLine produces a variety of welding products including these customized welding guns.

Epicor Quick Ship has helped to deliver further improvements for CenterLine. "Epicor Quick Ship allows CenterLine to process huge and increasing volumes of sales without needing additional staff," explained Beneteau. "Before, we processed around 150 sales lines a day. Now we have tripled our daily throughput and recently hit 420 sales lines in one day. That is amazing."

Epicor incorporates a clean and easy tool to self-serve data more efficiently. Departments can run data queries, analyze data and generate their own dashboards without technical help. For instance, Procurement uses Epicor to build specialized purchasing reports that show information such as consumption and patterns with suppliers, while a user in manufacturing builds an auditing dashboard.

"These are just two examples of users who were able to get information they need off the cuff, without having to wait for someone in IT," disclosed Beneteau. "It shows how Epicor helps us head off business problems quicker by analyzing data and generating reports ourselves in real time."

Supporting Business Growth

Another important area of production where Epicor has replaced a manual process with automation is lot tracing and tracking. CenterLine uses specialized copper and metal powders in its products and consumables, and the quality of these raw materials can vary. If a customer reports a problem with a material, Epicor records the information and then automatically back-tracks the material lot to identify where it came from and if it was used by other customers.

With a commitment to supplying customers with state-of-the-art resistance welding equipment, components, and consumables, CenterLine remains at the forefront of resistance welding technology.

"Changing the ERP system to Epicor was a strategic move for CenterLine and is essential to our growth trajectory," concluded Beneteau. "Epicor has eliminated the pains and struggles of our previous system. While change is painful, looking back on what we have gained and considering what we might have chosen, we are glad we chose Epicor. It fits with our business culture and provides the flexibility to tweak and modify manufacturing and procurement to support the business and our growth effectively."

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::