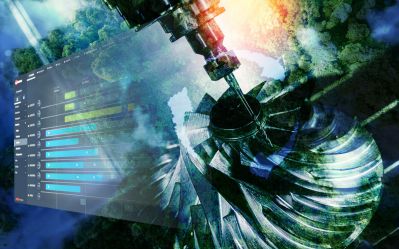

Updated Management Software Helps CNC Manufacturers Measure, Report and Optimize Their Sustainability Efforts

CNC manufacturers all over the world are looking for ways to measure, report and optimize their sustainability efforts as the demand for sustainability grows. Fastems' MMS version 8.2 automation control software is developed to help manufacturers in achieving their sustainability goals, especially in the area of high-mix manufacturing.

Automating CNC machines has always been a sustainable choice. Benefits include safer jobs; increased profitability; and reduced manufacturing emissions by half achievable by lessening machining, facility energy consumption, scrap, outsourcing and logistics. With more than 5,000 automation systems installed globally and a willingness to learn from its customers, Fastems has implemented new features into their automation systems to help manufacturers fulfill their sustainability measuring and reporting obligations.

One of the most important requirements for a manufacturer is to begin measuring and reporting the carbon footprint of their produced parts. MMS 8.2 measures and reports the machine tool energy consumption of each NC program, allowing the manufacturers to calculate the energy usage in part level. The information can also be used to adjust the inefficient NC programs, or running certain parts overnight when the electricity demand is lower.

To minimize unnecessary energy usage, the new "Auto-Power On/Off" function turns machine tools off automatically when there are no planned NC-programs to run. With the automatic wake function, the machine starts and warms up before the next NC-program start time.

VIDEO: Factory Automation -- Why Should You Care?

Since metal is a non-renewable and valuable resource, recycling is an extremely important to sustainability efforts. MMS 8.2 comes with a material-dedicated feature that allows users to rout the jobs with specific material to specific machine tools. This way, high-quality chips can be easily separated and recycled.

"When it comes to CNC automation, sustainability and profitability go hand in hand. The idea of automation is to remove the unnecessary, frustrating, and repetitive work -- and our goal is to also make the sustainability work as easy as possible for our customers," said Heikki Hallila, Vice President of Digital Manufacturing and Automation at Fastems.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::