Ibarmia's Latest Machining Center Replaces the Conventional Fixed Table

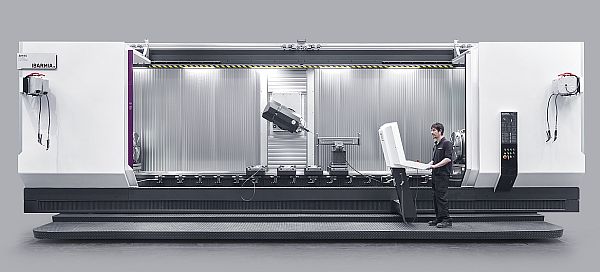

The latest addition to the Ibarmia machine line, the ZVH 55/L6000 EXTREME, is making waves with its revolutionary approach to reducing preparation times and maximizing productivity, according to the company.

Designed specifically for textile machinery part production, this machining center once again underscores the versatility of IBARMIA's moving column architecture in meeting a wide range of production requirements.

What sets the ZVH 55/L6000 EXTREME apart is its innovative use of 6 sliding platforms on 2 guideways, replacing the conventional fixed table. A pneumatic system unlocks these platforms, allowing for manual movement along with all the fixtures attached, such as bolt-on rotary tables, steady rests, jaws, and other clamping devices. This agile and efficient setup enables swift adaptation to varying workpiece lengths, drastically reducing setup times.

Moreover, integrated zero points on these tables facilitate rapid interchangeability of clamping devices, resulting in significant time savings during production.

With a longitudinal travel of up to 6000 mm, combined with the mobility of its column and the high dynamics of the continuous B-axis tilting head with torque motor, the ZVH 55/L6000 EXTREME is ideal for manufacturing long pieces of various lengths, ensuring elevated productivity levels.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::