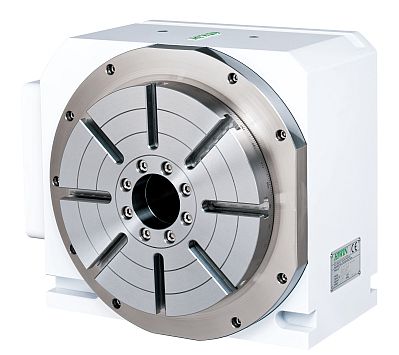

Torque Motor Rotary Tables Brings 5-Axis Capability to 3-Axis Machines

HIWIN Corporation will be highlighting its Torque Motor Rotary Tables (TMRT) at IMTS this September in Chicago.

Designed for machine tool OEM's and retrofitters, the TMRT series enables 3 axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even 5 axis capability.

High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

HIWIN's TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The TMRT series is compatible with most major CNC brands, making control integration straightforward.

HIWIN Torque Motor Rotary Tables utilize HIWIN's torque motor components, which are also available for engineers who prefer to design and build a unique table.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::