March 2008 Edition

imports, exports

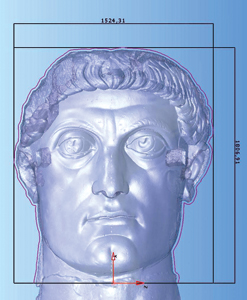

'Now program me the head of the Emperor Constantine'

The emperor gets the imperial five-axis treatment.

The emperor gets the imperial five-axis treatment.

Most people who work with machining software often

think in terms of wing spars, aerospace blisks, and auto

subassemblies.

Once in a while, though, there's the unique

request — say, programming to make a replica of the head of the

Roman Emperor Constantine, considered the ancient empire's first

Christian ruler.

In one of its largest and most unusual projects

to date, Germany's Delcam GmbH developed programs to machine the

giant replica. The 2½m head was needed for an exhibition in Trier,

Germany, after it was determined that the original pieces were too

heavy and too delicate to be shipped from Rome.

Delcam engineers started the project with a STL

file created by ArcTron 3D, using a combination of laser scanning

and structured light scanning. The size and complexity of the file

had already defeated several other CAD/CAM companies, but it could

be processed using PowerMILL, one of very few CAM systems developed

from day one to be able to machine STL files.

The next problem was the material to be used – a

25-ton block of marble.

"Marble was completely new territory for us,"

admits Delcam's sales manager Ferdi Hoischen. "We had absolutely no

data on milling tools, cutting values, or suitable processing

strategies for this material. Following intensive research on the

tools and after comprehensive tests of various machining strategies

in cooperation with EEW Maschinenbau GmbH in Kiel, we were finally

able to start the programming of the Emperor's bust."

A further challenge came because CAM specialist

Ingo Busse could not be present at EEW for all the time needed for

the NC programming.

"I had to undertake much of the programming using

geometry based on the residual material model in PowerMILL," says

Busse. "I had to be able to rely completely on the accuracy of the

roughing programs created by PowerMILL when programming the

finishing tool paths."

The task was made even more difficult by the fact

that five-axis machining had to be used for parts of the bust.

Overall, a total of 230 NC programs were produced

in this way. When they were run by EEW, PowerMILL fully justified

the confidence placed in the software's ability to calculate the

residual material model and to undertake collision checking of the

milling machine.

The close cooperation between Delcam and EEW was

largely responsible for the successful completion of the project.

"Only with an expert team of top-quality software

and the latest milling machine technology can such challenges as the

bust of Emperor Constantine be mastered," says Hoischen. "Without

efficient and innovative CAM software, every milling machine will

soon be what Emperor Constantine is today – history."

Delcam International Inc.

Ex-Im Bank support

Ancient meets modern as Emperor Constantine is immortalized in the world of CAD/CAM.

Ancient meets modern as Emperor Constantine is immortalized in the world of CAD/CAM.

America's manufacturing technology equipment

suppliers need support from the Export-Import Bank of the United

States to secure export orders that will keep their companies alive

and safeguard jobs in the United States. That message was recently

delivered to the House Committee on Small Business by Steven A.

Thiry, vice president of business development for AMT-The

Association For Manufacturing Technology.

"Increasingly, the ability to compete in the

global markets is determined by factors beyond the products offered

and the manufacturer's ability to service and support those products

at the customer's point of use," he testified. Foreign competitors

can often obtain government subsidized financing that substantially

improves their competitive position. That means foreign buyers

"often must pay substantially greater credit insurance and interest

rates and undergo a difficult and uncertain application process in

order to acquire American technology," Thiry added.

He urged that Congress ensure that the Ex-Im Bank have adequate

staffing and funding to work with U.S. firms.

Finally, current U.S. content requirements should

be reviewed. As customers in export markets seek to reduce the

number of vendors and orders they transact, American exporters are

often forced to bundle their U.S.-made products with foreign-made

goods.

"When financing support is offered only in proportion to American

content, it puts the American exporter at a substantial disadvantage

to foreign competition who can and will finance the entire project,"

Thiry said.

AMT-The Association For Manufacturing Technology

What do you think?

Will the information in this article increase efficiency or

save time, money, or effort? Let us know by e-mail from our

website at

www.ToolingandProduction.com or e-mail the editor at

dseeds@nelsonpub.com.