July 2008 Edition

fluid management

Safer and greener

Auto partsmaker improves environment and saves over $340,000

Grounding clamps in Flex-N-Gate’s painting line required daily cleaning, and

the only effective process was to soak the clamps and cables in MEK solvent.

Here they are being prepared for the new cleaning method.

Grounding clamps in Flex-N-Gate’s painting line required daily cleaning, and

the only effective process was to soak the clamps and cables in MEK solvent.

Here they are being prepared for the new cleaning method.

Despite meeting industry standards for quality manufacturing,

Flex-N-Gate Corp. of Ada, OK, needed to address environmental

concerns about the hazardous chemicals used in its manufacture of

bumper and fascia systems for automobiles.

Through creative fluid management and a bit of ingenuity,

Flex-N-Gate saved more than $340,000 over a three-year period.

Flex-N-Gate employs over 13,000 people at 50 manufacturing plants

and six product development and engineering facilities throughout

North America, Mexico, Argentina, and Spain.

At the Ada facility, Flex-N-Gate uses thermoplastic injection and

gas-assist molding operations to produce large body and mold-in

color automotive parts. In a recent year, the facility produced 2.9

million parts in its 366,000-square foot manufacturing space, which

is TS16949- and ISO 14001-certified.

While Flex-N-Gate was a minor source emitter of hazardous air

pollutants (HAP), it needed to follow regulations under the

Environmental Protection Agency’s Clean Air Act, which bans certain

chemicals. This list includes methyl ethyl ketone (MEK), a

hazardous, carcinogenic chemical that the automotive industry is

moving away from using.

Hazardous air pollutants

In 1990, Congress

enacted changes to the federal Clean Air Act, including a regulatory program

designed to reduce hazardous air pollutant (HAP) emissions. The legislation

included a list of 189 chemicals and chemical categories that are classified as

HAPs.

The EPA regulations focus on the amount of HAPs that may be

emitted into the air, not the amount that may be used in production.

For this reason, facilities have the option to install a control

device to meet the regulations. Flex-N-Gate used a regenerative

thermal oxidizer to destroy emissions at 98-percent efficiency, but

it still had a small amount of HAPs and volatile organic compounds

(VOCs) that it needed to control by other means such as a non-HAP,

low-VOC purge solvent.

To address reducing HAP and VOC emissions, Flex-N-Gate Oklahoma

contracted with Houghton Fluidcare, a fluid management consultant.

The consultant’s goal was to help Flex-N-Gate optimize chemical use

by procuring less hazardous chemicals for manufacturing operations.

The crux of Flex-N-Gate’s fluid management plan was to

purge its solvent program by reducing HAP chemicals. To date,

this process has drastically reduced hazardous emissions.

Over

a three-year period, the fluid management contract guaranteed

Flex-N-Gate a 15-percent cost savings in chemicals — 10 percent the

first year, 3 percent the second year and 2 percent the third year —

by decreasing the use of HAP solvents/chemicals and changing

chemical usages to make Flex-N-Gate Oklahoma a more environmentally

friendly manufacturing facility.

Over

a three-year period, the fluid management contract guaranteed

Flex-N-Gate a 15-percent cost savings in chemicals — 10 percent the

first year, 3 percent the second year and 2 percent the third year —

by decreasing the use of HAP solvents/chemicals and changing

chemical usages to make Flex-N-Gate Oklahoma a more environmentally

friendly manufacturing facility.

When the program kicked off, the consultant firm provided

Flex-N-Gate with a site manager to analyze the chemicals used in its

painting operations and evaluate its waste management system.

"Many consultants only look at the waste stream operations, but

that’s not how it worked for us," says Tyson Brown, environmental

manager at Flex-N-Gate Oklahoma. "We analyzed the chemistry up

front, as well as the entire waste stream. We also considered the

full battery of waste treatment tools and the latest recycling

technology to start to move Flex-N-Gate toward better environmental

performance."

Reducing MEK solvent

Flex-N-Gate had been interested in eliminating the use of MEK

cleaning solvent, which it had used in painting operations since the

1970s.

In the past, the grounding clamps in Flex-N-Gate’s painting line

required daily cleaning, and the only effective process was to soak

the clamps and cables in MEK solvent. The site manager helped

Flex-N-Gate find a non-hazardous, water-based system (utilizing a

water-based paint and ink remover) through which it has been able to

reduce MEK use in its facility. This was a change from 110

gallons/month of MEK to 55 gallons/month in the first six months and

to zero after eight months of the fluid management program.

The new cleaning process uses an automated soak system. An Arm &

Hammer Safety Clean fluid is heated to 170 degrees in a soaking

tank. When ready for cleaning, cables are placed on a tray and

lowered into the tank. An agitator activates the cleaning process,

and the cables soak for 12 hours. Once removed, the clamps and

cables are immediately ready for reuse.

"This process has helped increase production by turning out a

better cable with less contamination," Brown says. "Because the

cleaner is water-based, it completely eliminates the hazardous

cleaning product we need to dispose of."

In addition to eliminating MEK, Flex-N-Gate was able to reduce

the use of other HAP solvents used in paint reduction.

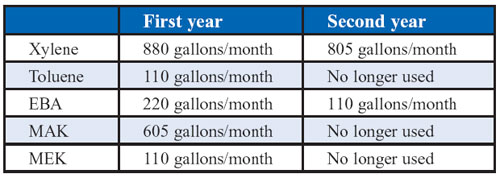

In the first year of its new fluid management program,

Flex-N-Gate Oklahoma significantly reduced its use of HAP solvents

and eliminated the use of two. The following is a comparison of

chemical usage showcasing one month in the first year and the same

month in the second year.

To reduce HAP solvent use, Flex-N-Gate replaced some of them with

non-HAP chemicals such as diacetone alcohol.

Solvent reclaim system

The new cleaning process uses an automated soak system. This tank contains

fluid heated to 170 degrees. After agitation and 12 hours of soaking, the

clamps and cables are immediately ready for reuse.

The new cleaning process uses an automated soak system. This tank contains

fluid heated to 170 degrees. After agitation and 12 hours of soaking, the

clamps and cables are immediately ready for reuse.

To dispose of used solvents in the past, Flex-N-Gate sent them to

an incinerator to be used as fuel. This came at the high-energy cost

of burning the chemicals. The site manager worked with Barton

Solvents Inc., Flex-N-Gate’s supplier, to find a company that would

remove the solvent and repackage it as a recycled solvent.

Barton donated 20 350-gallon totes to Flex-N-Gate to gather waste solvent via

an accumulation system. Once operators move the solvent to storage, they contact

a reclamation company for pick-up every five to six weeks. This saves the

facility about $6,300 in hazardous waste removal costs every six to seven weeks

or about $46,000 annually. This is a 40-percent drop in waste disposal costs.

Flex-N-Gate was able to build solvent disposal into its vendor costs,

eliminating that waste stream’s hazardous waste disposal costs.

The crux of Flex-N-Gate’s fluid management plan was to purge its solvent

program by reducing HAP chemicals. To date, this process has drastically reduced

hazardous emissions. Flex-N-Gate even received the Gold Star Award for pollution

prevention from the Oklahoma Department of Environmental Quality.

Contracting with a third-party consultant has been invaluable to Flex-N-Gate

Oklahoma, Brown says. Having an onsite office for the consultant has allowed him

to be there day in and day out to provide on-the-spot information and advice.

Houghton International

What do you think?

Will the information in this article increase efficiency or

save time, money, or effort? Let us know by e-mail from our website at

www.ToolingandProduction.com or e-mail the editor at

dseeds@nelsonpub.com.