July 2008 Edition

SPC software

At their fingertips

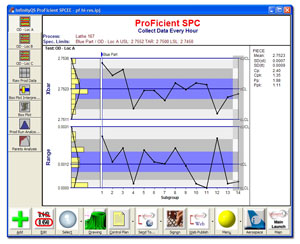

Software monitors and charts product quality data in real-time

SPC

software plots data on a graph or graphs for analysis.

SPC

software plots data on a graph or graphs for analysis.

With annual sales of $21.9 billion, Raytheon Co., a company

dealing with defense and government electronics, space, information

technology, technical services, and business and special mission

aircraft, didn’t get to be an industry leader by accident.

In its mission for a quality control process that had to be

precise and accurate, Raytheon turned to software for real-time data

collection and analysis. The company is using InfinityQS’ real-time

Statistical Process Control (SPC) Software to improve product

quality by identifying areas that need improvement.

Competition is driving companies to innovate, especially to

produce higher quality products at a low cost. Quality issues

resulting in scrap or rework, and production inefficiencies such as

over-inspection, manual data collection and/or incapable machines,

create unique challenges for manufacturers looking to maximize

production capabilities.

Raytheon’s Vision, Strategy, Goals and Values are the foundation

of the company, as is a commitment for strategic growth,

establishing an inclusive culture, improving productivity, and

providing customers with Mission Systems Integration, Mission

Support and Mission Assurance for each product and servicer.

Overcoming complex challenges requires solutions that interact

with existing infrastructures while offering the scalability to grow

with business needs, a low cost, and high ROI.

Raytheon required powerful, feature-rich analytics software to

enable real-time process management as silicon wafers were produced

with highly precise specifications.

With real-time SPC software, operators on the plant

floor collect measurements from products as they are being

produced. The software then plots this data on a graph or a

series of graphs so that quality inspectors can determine if the

process is performing within an acceptable statistical range.

To gain a competitive advantage, companies today are employing

continuous improvement activities that contribute to manufacturing

excellence by monitoring the variation that naturally occurs in

manufacturing processes (or machines), as well as the processes

themselves.

Because Raytheon provides state-of-the-art electronics, mission

systems integration and other mission support services to the

defense industry, it is vital for the company to achieve the highest

standards of quality. Raytheon’s culture encourages the development

of innovative process improvements that create value for customers.

The company requires 100 percent accuracy with its products, and

to meet this specification, it required that all the software in the

manufacturing line be compatible.

SPC is a widely used statistical method for quantifying process

characteristics, pointing to areas where process improvement can be

made.

"Due to the precise specifications of our silicon wafers,

accuracy is important and the ability to have quality information at

our fingertips in real-time was a key aspect in the selection of

InfinityQS’ SPC software," says David Liu, quality engineer at

Raytheon.

An industry-standard methodology for measuring and controlling

quality during the manufacturing process, real-time SPC identifies

quality issues before defects are created.

"Accurate, correctly calculated control limits can help

manufacturers reduce costs, improve quality, and increase customer

retention," says Douglas C. Fair, industrial statistician and vice

president of statistical applications at InfinityQS International.

"Through their proper use, control limits can mean a big difference

in terms of product quality and costs."

SPC software’s prime objectives are to provide information about

production processes in real-time. Successful real-time SPC

initiatives require that measurement data be accurate and collected

in a timely manner. Various gaging devices must be used to ensure

that a specific measurement is taken and recorded. SPC software

systems collect and store this data, analyze it and create graphs

instantaneously.

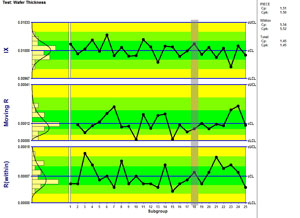

Monitoring wafer thickness is crucial at Ravtheon.

Monitoring wafer thickness is crucial at Ravtheon.

Each new data point offers an opportunity to make a process

change or do nothing. Effective real-time SPC software should be

able to provide alerts when process changes are necessary.

With real-time SPC software, operators on the plant floor collect

attribute data (measurements) from products as they are being

produced. The software then plots this data on a graph or a series

of graphs so that quality professionals can determine if the process

is performing within an acceptable statistical range.

This accepted range, defined by upper and lower "control limits,"

allows quality professionals to pinpoint exactly which processes

(machines) need to be adjusted to prevent the product from having

defects.

Raytheon conducted a comprehensive analysis of InfinityQS SPC

software to ensure that the system met the requirements of its

quality engineers. InfinityQS’ open platform allowed for a seamless

integration across the facility’s entire manufacturing line,

ensuring accurate, real-time data.

"Raytheon came to us with clear specifications deemed necessary

for its plants," says Michael A. Lyle, president and CEO of

InfinityQS. "Quality is a key component of wafer technology, and

Raytheon concluded that our SPC software solution met their high

standards. "

Using InfinityQS software, Raytheon is able to chart and monitor

variations lot-to-lot, wafer-to-wafer, and die-to-die within wafers.

"My engineers learned to navigate and use the software very

easily because of its intuitive design and functionality," Liu says.

"The security of the software, one of our major concerns when

searching for an SPC solution, has exceeded our expectations."

Raytheon continues to benefit from the software’s depth of

functionality, such as its integration capabilities, security

features, and wide variety of charting options, he adds.

InfinityQS

What do you think?

Will the information in this article increase efficiency or

save time, money, or effort? Let us know by e-mail from our website at

www.ToolingandProduction.com or e-mail the editor at

dseeds@nelsonpub.com.